IEEE Spectrum IEEE Spectrum

-

Video Friday: 1X Robots Tidy Up

by Evan Ackerman on 07. June 2024. at 16:00

Video Friday is your weekly selection of awesome robotics videos, collected by your friends at IEEE Spectrum robotics. We also post a weekly calendar of upcoming robotics events for the next few months. Please send us your events for inclusion.

RoboCup 2024: 17–22 July 2024, EINDHOVEN, NETHERLANDS

ICRA@40: 23–26 September 2024, ROTTERDAM, NETHERLANDS

IROS 2024: 14–18 October 2024, ABU DHABI, UNITED ARAB EMIRATES

ICSR 2024: 23–26 October 2024, ODENSE, DENMARK

Cybathlon 2024: 25–27 October 2024, ZURICH

Enjoy today’s videos!

In this video, you see the start of 1X’s development of an advanced AI system that chains simple tasks into complex actions using voice commands, allowing seamless multi-robot control and remote operation. By starting with single-task models, we ensure smooth transitions to more powerful unified models, ultimately aiming to automate high-level actions using AI.

This video does not contain teleoperation, computer graphics, cuts, video speedups, or scripted trajectory playback. It’s all controlled via neural networks.

[ 1X ]

As the old adage goes, one cannot claim to be a true man without a visit to the Great Wall of China. XBot-L, a full-sized humanoid robot developed by Robot Era, recently acquitted itself well in a walk along sections of the Great Wall.

[ Robot Era ]

The paper presents a novel rotary wing platform, that is capable of folding and expanding its wings during flight. Our source of inspiration came from birds’ ability to fold their wings to navigate through small spaces and dive. The design of the rotorcraft is based on the monocopter platform, which is inspired by the flight of Samara seeds.

[ AirLab ]

We present a variable stiffness robotic skin (VSRS), a concept that integrates stiffness-changing capabilities, sensing, and actuation into a single, thin modular robot design. Reconfiguring, reconnecting, and reshaping VSRSs allows them to achieve new functions both on and in the absence of a host body.

[ Yale Faboratory ]

Heimdall is a new rover design for the 2024 University Rover Challenge (URC). This video shows highlights of Heimdall’s trip during the four missions at URC 2024.

Heimdall features a split body design with whegs (wheel legs), and a drill for sub-surface sample collection. It also has the ability to manipulate a variety of objects, collect surface samples, and perform onboard spectrometry and chemical tests.

[ WVU ]

I think this may be the first time I’ve seen an autonomous robot using a train? This one is delivering lunch boxes!

[ JSME ]

The AI system used identifies and separates red apples from green apples, after which a robotic arm picks up the red apples identified with a qb SoftHand Industry and gently places them in a basket.

My favorite part is the magnetic apple stem system.

[ QB Robotics ]

DexNex (v0, June 2024) is an anthropomorphic teleoperation testbed for dexterous manipulation at the Center for Robotics and Biosystems at Northwestern University. DexNex recreates human upper-limb functionality through a near 1-to-1 mapping between Operator movements and Avatar actions.

Motion of the Operator’s arms, hands, fingers, and head are fed forward to the Avatar, while fingertip pressures, finger forces, and camera images are fed back to the Operator. DexNex aims to minimize the latency of each subsystem to provide a seamless, immersive, and responsive user experience. Future research includes gaining a better understanding of the criticality of haptic and vision feedback for different manipulation tasks; providing arm-level grounded force feedback; and using machine learning to transfer dexterous skills from the human to the robot.

[ Northwestern ]

Sometimes the best path isn’t the smoothest or straightest surface, it’s the path that’s actually meant to be a path.

[ RaiLab ]

Fulfilling a school requirement by working in a Romanian locomotive factory one week each month, Daniela Rus learned to operate “machines that help us make things.” Appreciation for the practical side of math and science stuck with Daniela, who is now Director of the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL).

[ MIT ]

For AI to achieve its full potential, non-experts need to be let into the development process, says Rumman Chowdhury, CEO and cofounder of Humane Intelligence. She tells the story of farmers fighting for the right to repair their own AI-powered tractors (which some manufacturers actually made illegal), proposing everyone should have the ability to report issues, patch updates or even retrain AI technologies for their specific uses.

[ TED ]

-

Errors in Navigational Models Could Have an Easy Answer

by Rahul Rao on 07. June 2024. at 11:00

Just as early mariners used simple compasses to chart courses across the sea, today’s ships, planes, satellites, and smartphones can rely on Earth’s magnetic field to find their bearings. The difference is that today’s rather more sophisticated compasses have the aid of complex models, like the commonly used World Magnetic Model (WMM), that try to capture the multifaceted processes that create Earth’s magnetosphere. A compass can rely on the WMM or similar models to convert a needle pointing to magnetic north to a heading with respect to true north. (The two norths differ by ever-changing angles.)

These models are not perfect: There are differences between the magnetosphere that they predict and the magnetosphere that satellites observe. Scientists have traditionally ascribed these differences to space currents that flow through the magnetic field high in Earth’s upper atmosphere. But new research complicates the picture, suggesting that the differences are the result of observational biases, incomplete models, or both.

For craft that require sensitive navigation, particularly around Earth’s poles, any of these complications pose a problem. And those problems stand to grow as polar ice melts around the North Pole, opening up potential new shipping routes.

Earth’s magnetic field is multifaceted and complex, but models like the WMM can project it out a few years at a time. The WMM’s current edition, released in December 2019, contains estimates of Earth’s magnetic field from the start of 2020 to the end of 2024. (The next version, covering 2025 through 2029, is scheduled for release in December of this year.)

“Compasses need to account for space currents already, but this adds more complication and sources of noise that have to be dealt with.” —Mark Moldwin, University of Michigan

These models do not always account for space currents, which are often pushed around by extraterrestrial forces like the solar wind. But if space currents are responsible for the discrepancies between models and observations, scientists could identify them by simply finding the differences, which they call “residuals.” Moreover, there would then be little reason for one of Earth’s hemispheres to display more residuals than the other—except that’s what existing models predict.

But the new study’s authors, space physicists Yining Shi and Mark Moldwin from the University of Michigan, had been among a number of researchers who had spotted an imbalance in residuals. More residuals seemed to emerge from the magnetic woodwork, so to speak, in the southern hemisphere than in the Northern Hemisphere. “We wanted to take a closer look at them,” Moldwin said.

Shi and Moldwin compared estimates between 2014 and 2020 from another Earth magnetic field model, IGRF-13, with observations from the European Space Agency’s Swarm mission, a trio of satellites that have continually measured Earth’s magnetic field since their 2014 launch.

When they focused on residuals over that time period, they did indeed find about 12 percent more major residuals in the Southern Hemisphere than in the Northern. All of these large residuals were found in the polar regions. Many were concentrated at latitudes of 70 degrees north and south, where scientists expect to find space currents.

But another spate of residuals were concentrated closer to Earth’s geographic poles, about 80 degrees north and south, where they have no obvious geophysical explanation. Moreover, the distributions of these poles differed—matching the fact that Earth’s geographic poles map to different magnetic coordinates.

This second peak in particular led the researchers to consider alternative explanations. It is possible, for instance, that IGRF-13 simply does not capture all of the factors driving Earth’s magnetosphere around the poles. But another cause could be the satellites themselves. Shi and Moldwin say that, because Swarm satellites reside in orbits that cross the poles, Earth’s northern and southern polar regions are overrepresented in their magnetic measurements.

“Compasses need to account for space currents already, but this adds more complication and sources of noise that have to be dealt with,” Moldwin said.

Now, Shi is examining these residuals more closely to pick apart the causes of the residuals—which ones have actual geophysical explanations and which are the result of statistical errors.

Shi and Moldwin published their work on 6 May in Journal of Geophysical Research: Space Physics.

-

This Japanese Aircraft Became a 5G Base Station

by Tim Hornyak on 06. June 2024. at 14:51

Skies over Tokyo are thick with air traffic these days amid an influx of international tourists. But one plane recently helped revive the dream of airborne Internet access for all. Researchers in Japan announced on 28 May that they have successfully tested 5G communications equipment in the 38 gigahertz band from an altitude of 4 kilometers.

The experiment was aimed at developing an aerial relay backhaul with millimeter-wave band links between ground stations and a simulated High-Altitude Platform Station (HAPS), a radio station aboard an uncrewed aircraft that stays aloft in the stratosphere for extended periods of time. A Cessna flying out of Chofu Airfield in western Tokyo was outfitted with a 38 GHz 5G base station and core network device, and three ground stations were equipped with lens antennas with automatic tracking.

With the Cessna as a relay station, the setup enabled communication between one ground station connected to the 5G terrestrial network and a terrestrial base station connected to a user terminal, according to a consortium of Japanese companies and the National Institute of Information and Communications Technology.

“We developed technology that enables communication using 5G [New Radio] by correctly directing 38 GHz beams toward three ground stations while adapting to the flight attitude, speed, direction, position, altitude, etc. during aircraft rotation,” said Shinichi Tanaka, a manager in broadcaster SKY Perfect JSAT’s Space Business Division. “We confirmed that the onboard system, designed for the stratosphere, has adequate communication and tracking performance even under the flight speed and attitude fluctuations of a Cessna aircraft, which are more severe than those of HAPS.”

The sharpest beam width of the ground station antenna is 0.8 degrees, and the trial demonstrated a tracking method that always captures the Cessna in this angular range, Tanaka added.

A Cessna [top left] carried a 38 GHz antenna [top right] during a flight, functioning as a 5G base station for receivers on the ground [bottom right]. The plane was able to connect to multiple ground stations at once [illustration, bottom left].NTT Docomo

A Cessna [top left] carried a 38 GHz antenna [top right] during a flight, functioning as a 5G base station for receivers on the ground [bottom right]. The plane was able to connect to multiple ground stations at once [illustration, bottom left].NTT DocomoMillimeter wave bands, such as the 38 GHz band, have the highest data capacity for 5G and are suited for crowded venues such as stadiums and shopping centers. When used outdoors, however, the signals can be attenuated by rain and other moisture in the atmosphere. To counter this, the consortium successfully tested an algorithm that automatically switches between multiple ground stations to compensate for moisture-weakened signals.

Unlike Google’s failed Loon effort, which focused on providing direct communication to user terminals, the HAPS trial is aimed at creating backhaul lines for base stations. Led by Japan’s Ministry of Internal Affairs and Communications, the experiment is designed to deliver high-speed, high-capacity communications both for the development of 5G and 6G networks as well as emergency response. The latter is critical in disaster-prone Japan—in January, communication lines around the Noto Peninsula on the Sea of Japan were severed following a magnitude-7 earthquake that caused over 1,500 casualties.

“This is the world’s first successful 5G communication experiment via the sky using the Q-band frequency,” said Hinata Kohara, a researcher with mobile carrier NTT Docomo’s 6G Network Innovation Department. “In addition, the use of 5G communication base stations and core network equipment on the aircraft for communication among multiple ground stations enables flexible and fast route switching of the ground [gateway] station for a feeder link, and is robust against propagation characteristics such as rainfall. Another key feature is the use of a full digital beamforming method for beam control, which uses multiple independent beams to improve frequency utilization efficiency.”

Doppler shift compensation was a challenge in the experiment, Kohara said, adding that the researchers will conduct further tests to find a solution with the aim of commercializing a HAPS service in 2026. Aside from SKY Perfect JSAT and NTT Docomo, the consortium includes Panasonic Holdings, known for its electronics equipment.

The HAPS push comes as NTT Docomo announced it has led another consortium in a $100 million investment in Airbus’ AALTO HAPS, operator of the Zephyr fixed-wing uncrewed aerial vehicle. The solar-powered wing can be used for 5G direct-to-device communications or Earth observation, and has set records including 64 days of stratospheric flight. According to Airbus, it has a reach of “up to 250 terrestrial towers in difficult mountainous terrain.” Docomo said the investment is aimed at commercializing Zephyr services in Japan, including coverage of rural areas and disaster zones, and around the world in 2026.

-

How Large Language Models Are Changing My Job

by Glenn Zorpette on 06. June 2024. at 13:59

Generative artificial intelligence, and large language models in particular, are starting to change how countless technical and creative professionals do their jobs. Programmers, for example, are getting code segments by prompting large language models. And graphic arts software packages such as Adobe Illustrator already have tools built in that let designers conjure illustrations, images, or patterns by describing them.

But such conveniences barely hint at the massive, sweeping changes to employment predicted by some analysts. And already, in ways large and small, striking and subtle, the tech world’s notables are grappling with changes, both real and envisioned, wrought by the onset of generative AI. To get a better idea of how some of them view the future of generative AI, IEEE Spectrum asked three luminaries—an academic leader, a regulator, and a semiconductor industry executive—about how generative AI has begun affecting their work. The three, Andrea Goldsmith, Juraj Čorba, and Samuel Naffziger, agreed to speak with Spectrum at the 2024 IEEE VIC Summit & Honors Ceremony Gala, held in May in Boston.

Click to read more thoughts from:

- Andrea Goldsmith, dean of engineering at Princeton University.

- Juraj Čorba, senior expert on digital regulation and governance, Slovak Ministry of Investments, Regional Development

- Samuel Naffziger, senior vice president and a corporate fellow at Advanced Micro Devices

Andrea Goldsmith

Andrea Goldsmith is dean of engineering at Princeton University.

There must be tremendous pressure now to throw a lot of resources into large language models. How do you deal with that pressure? How do you navigate this transition to this new phase of AI?

Andrea J. Goldsmith

Andrea J. Goldsmith Andrea Goldsmith: Universities generally are going to be very challenged, especially universities that don’t have the resources of a place like Princeton or MIT or Stanford or the other Ivy League schools. In order to do research on large language models, you need brilliant people, which all universities have. But you also need compute power and you need data. And the compute power is expensive, and the data generally sits in these large companies, not within universities.

So I think universities need to be more creative. We at Princeton have invested a lot of money in the computational resources for our researchers to be able to do—well, not large language models, because you can’t afford it. To do a large language model… look at OpenAI or Google or Meta. They’re spending hundreds of millions of dollars on compute power, if not more. Universities can’t do that.

But we can be more nimble and creative. What can we do with language models, maybe not large language models but with smaller language models, to advance the state of the art in different domains? Maybe it’s vertical domains of using, for example, large language models for better prognosis of disease, or for prediction of cellular channel changes, or in materials science to decide what’s the best path to pursue a particular new material that you want to innovate on. So universities need to figure out how to take the resources that we have to innovate using AI technology.

We also need to think about new models. And the government can also play a role here. The [U.S.] government has this new initiative, NAIRR, or National Artificial Intelligence Research Resource, where they’re going to put up compute power and data and experts for educators to use—researchers and educators.

That could be a game-changer because it’s not just each university investing their own resources or faculty having to write grants, which are never going to pay for the compute power they need. It’s the government pulling together resources and making them available to academic researchers. So it’s an exciting time, where we need to think differently about research—meaning universities need to think differently. Companies need to think differently about how to bring in academic researchers, how to open up their compute resources and their data for us to innovate on.

As a dean, you are in a unique position to see which technical areas are really hot, attracting a lot of funding and attention. But how much ability do you have to steer a department and its researchers into specific areas? Of course, I’m thinking about large language models and generative AI. Is deciding on a new area of emphasis or a new initiative a collaborative process?

Goldsmith: Absolutely. I think any academic leader who thinks that their role is to steer their faculty in a particular direction does not have the right perspective on leadership. I describe academic leadership as really about the success of the faculty and students that you’re leading. And when I did my strategic planning for Princeton Engineering in the fall of 2020, everything was shut down. It was the middle of COVID, but I’m an optimist. So I said, “Okay, this isn’t how I expected to start as dean of engineering at Princeton.” But the opportunity to lead engineering in a great liberal arts university that has aspirations to increase the impact of engineering hasn’t changed. So I met with every single faculty member in the School of Engineering, all 150 of them, one-on-one over Zoom.

And the question I asked was, “What do you aspire to? What should we collectively aspire to?” And I took those 150 responses, and I asked all the leaders and the departments and the centers and the institutes, because there already were some initiatives in robotics and bioengineering and in smart cities. And I said, “I want all of you to come up with your own strategic plans. What do you aspire to in these areas? And then let’s get together and create a strategic plan for the School of Engineering.” So that’s what we did. And everything that we’ve accomplished in the last four years that I’ve been dean came out of those discussions, and what it was the faculty and the faculty leaders in the school aspired to.

So we launched a bioengineering institute last summer. We just launched Princeton Robotics. We’ve launched some things that weren’t in the strategic plan that bubbled up. We launched a center on blockchain technology and its societal implications. We have a quantum initiative. We have an AI initiative using this powerful tool of AI for engineering innovation, not just around large language models, but it’s a tool—how do we use it to advance innovation and engineering? All of these things came from the faculty because, to be a successful academic leader, you have to realize that everything comes from the faculty and the students. You have to harness their enthusiasm, their aspirations, their vision to create a collective vision.

Juraj Čorba

Juraj Čorba is senior expert on digital regulation and governance, Slovak Ministry of Investments, Regional Development, and Information, and Chair of the Working Party on Governance of AI at the Organization for Economic Cooperation and Development.

What are the most important organizations and governing bodies when it comes to policy and governance on artificial intelligence in Europe?

Juraj Čorba

Juraj ČorbaJuraj Čorba: Well, there are many. And it also creates a bit of a confusion around the globe—who are the actors in Europe? So it’s always good to clarify. First of all we have the European Union, which is a supranational organization composed of many member states, including my own Slovakia. And it was the European Union that proposed adoption of a horizontal legislation for AI in 2021. It was the initiative of the European Commission, the E.U. institution, which has a legislative initiative in the E.U. And the E.U. AI Act is now finally being adopted. It was already adopted by the European Parliament.

So this started, you said 2021. That’s before ChatGPT and the whole large language model phenomenon really took hold.

Čorba: That was the case. Well, the expert community already knew that something was being cooked in the labs. But, yes, the whole agenda of large models, including large language models, came up only later on, after 2021. So the European Union tried to reflect that. Basically, the initial proposal to regulate AI was based on a blueprint of so-called product safety, which somehow presupposes a certain intended purpose. In other words, the checks and assessments of products are based more or less on the logic of the mass production of the 20th century, on an industrial scale, right? Like when you have products that you can somehow define easily and all of them have a clearly intended purpose. Whereas with these large models, a new paradigm was arguably opened, where they have a general purpose.

So the whole proposal was then rewritten in negotiations between the Council of Ministers, which is one of the legislative bodies, and the European Parliament. And so what we have today is a combination of this old product-safety approach and some novel aspects of regulation specifically designed for what we call general-purpose artificial intelligence systems or models. So that’s the E.U.

By product safety, you mean, if AI-based software is controlling a machine, you need to have physical safety.

Čorba: Exactly. That’s one of the aspects. So that touches upon the tangible products such as vehicles, toys, medical devices, robotic arms, et cetera. So yes. But from the very beginning, the proposal contained a regulation of what the European Commission called stand-alone systems—in other words, software systems that do not necessarily command physical objects. So it was already there from the very beginning, but all of it was based on the assumption that all software has its easily identifiable intended purpose—which is not the case for general-purpose AI.

Also, large language models and generative AI in general brings in this whole other dimension, of propaganda, false information, deepfakes, and so on, which is different from traditional notions of safety in real-time software.

Čorba: Well, this is exactly the aspect that is handled by another European organization, different from the E.U., and that is the Council of Europe. It’s an international organization established after the Second World War for the protection of human rights, for protection of the rule of law, and protection of democracy. So that’s where the Europeans, but also many other states and countries, started to negotiate a first international treaty on AI. For example, the United States have participated in the negotiations, and also Canada, Japan, Australia, and many other countries. And then these particular aspects, which are related to the protection of integrity of elections, rule-of-law principles, protection of fundamental rights or human rights under international law—all these aspects have been dealt with in the context of these negotiations on the first international treaty, which is to be now adopted by the Committee of Ministers of the Council of Europe on the 16th and 17th of May. So, pretty soon. And then the first international treaty on AI will be submitted for ratifications.

So prompted largely by the activity in large language models, AI regulation and governance now is a hot topic in the United States, in Europe, and in Asia. But of the three regions, I get the sense that Europe is proceeding most aggressively on this topic of regulating and governing artificial intelligence. Do you agree that Europe is taking a more proactive stance in general than the United States and Asia?

Čorba: I’m not so sure. If you look at the Chinese approach and the way they regulate what we call generative AI, it would appear to me that they also take it very seriously. They take a different approach from the regulatory point of view. But it seems to me that, for instance, China is taking a very focused and careful approach. For the United States, I wouldn’t say that the United States is not taking a careful approach because last year you saw many of the executive orders, or even this year, some of the executive orders issued by President Biden. Of course, this was not a legislative measure, this was a presidential order. But it seems to me that the United States is also trying to address the issue very actively. The United States has also initiated the first resolution of the General Assembly at the U.N. on AI, which was passed just recently. So I wouldn’t say that the E.U. is more aggressive in comparison with Asia or North America, but maybe I would say that the E.U. is the most comprehensive. It looks horizontally across different agendas and it uses binding legislation as a tool, which is not always the case around the world. Many countries simply feel that it’s too early to legislate in a binding way, so they opt for soft measures or guidance, collaboration with private companies, et cetera. Those are the differences that I see.

Do you think you perceive a difference in focus among the three regions? Are there certain aspects that are being more aggressively pursued in the United States than in Europe or vice versa?

Čorba: Certainly the E.U. is very focused on the protection of human rights, the full catalog of human rights, but also, of course, on safety and human health. These are the core goals or values to be protected under the E.U. legislation. As for the United States and for China, I would say that the primary focus in those countries—but this is only my personal impression—is on national and economic security.

Samuel Naffziger

Samuel Naffziger is senior vice president and a corporate fellow at Advanced Micro Devices, where he is responsible for technology strategy and product architectures. Naffziger was instrumental in AMD’s embrace and development of chiplets, which are semiconductor dies that are packaged together into high-performance modules.

To what extent is large language model training starting to influence what you and your colleagues do at AMD?

Samuel Naffziger

Samuel NaffzigerSamuel Naffziger: Well, there are a couple levels of that. LLMs are impacting the way a lot of us live and work. And we certainly are deploying that very broadly internally for productivity enhancements, for using LLMs to provide starting points for code—simple verbal requests, such as “Give me a Python script to parse this dataset.” And you get a really nice starting point for that code. Saves a ton of time. Writing verification test benches, helping with the physical design layout optimizations. So there’s a lot of productivity aspects.

The other aspect to LLMs is, of course, we are actively involved in designing GPUs [graphics processing units] for LLM training and for LLM inference. And so that’s driving a tremendous amount of workload analysis on the requirements, hardware requirements, and hardware-software codesign, to explore.

So that brings us to your current flagship, the Instinct MI300X, which is actually billed as an AI accelerator. How did the particular demands influence that design? I don’t know when that design started, but the ChatGPT era started about two years ago or so. To what extent did you read the writing on the wall?

Naffziger: So we were just into the MI300—in 2019, we were starting the development. A long time ago. And at that time, our revenue stream from the Zen [an AMD architecture used in a family of processors] renaissance had really just started coming in. So the company was starting to get healthier, but we didn’t have a lot of extra revenue to spend on R&D at the time. So we had to be very prudent with our resources. And we had strategic engagements with the [U.S.] Department of Energy for supercomputer deployments. That was the genesis for our MI line—we were developing it for the supercomputing market. Now, there was a recognition that munching through FP64 COBOL code, or Fortran, isn’t the future, right? [laughs] This machine-learning [ML] thing is really getting some legs.

So we put some of the lower-precision math formats in, like Brain Floating Point 16 at the time, that were going to be important for inference. And the DOE knew that machine learning was going to be an important dimension of supercomputers, not just legacy code. So that’s the way, but we were focused on HPC [high-performance computing]. We had the foresight to understand that ML had real potential. Although certainly no one predicted, I think, the explosion we’ve seen today.

So that’s how it came about. And, just another piece of it: We leveraged our modular chiplet expertise to architect the 300 to support a number of variants from the same silicon components. So the variant targeted to the supercomputer market had CPUs integrated in as chiplets, directly on the silicon module. And then it had six of the GPU chiplets we call XCDs around them. So we had three CPU chiplets and six GPU chiplets. And that provided an amazingly efficient, highly integrated, CPU-plus-GPU design we call MI300A. It’s very compelling for the El Capitan supercomputer that’s being brought up as we speak.

But we also recognize that for the maximum computation for these AI workloads, the CPUs weren’t that beneficial. We wanted more GPUs. For these workloads, it’s all about the math and matrix multiplies. So we were able to just swap out those three CPU chiplets for a couple more XCD GPUs. And so we got eight XCDs in the module, and that’s what we call the MI300X. So we kind of got lucky having the right product at the right time, but there was also a lot of skill involved in that we saw the writing on the wall for where these workloads were going and we provisioned the design to support it.

Earlier you mentioned 3D chiplets. What do you feel is the next natural step in that evolution?

Naffziger: AI has created this bottomless thirst for more compute [power]. And so we are always going to be wanting to cram as many transistors as possible into a module. And the reason that’s beneficial is, these systems deliver AI performance at scale with thousands, tens of thousands, or more, compute devices. They all have to be tightly connected together, with very high bandwidths, and all of that bandwidth requires power, requires very expensive infrastructure. So if a certain level of performance is required—a certain number of petaflops, or exaflops—the strongest lever on the cost and the power consumption is the number of GPUs required to achieve a zettaflop, for instance. And if the GPU is a lot more capable, then all of that system infrastructure collapses down—if you only need half as many GPUs, everything else goes down by half. So there’s a strong economic motivation to achieve very high levels of integration and performance at the device level. And the only way to do that is with chiplets and with 3D stacking. So we’ve already embarked down that path. A lot of tough engineering problems to solve to get there, but that’s going to continue.

And so what’s going to happen? Well, obviously we can add layers, right? We can pack more in. The thermal challenges that come along with that are going to be fun engineering problems that our industry is good at solving.

-

IEEE Offers New Transportation Platform With Advanced Analytics Tools

by Kathy Pretz on 05. June 2024. at 18:00

To help find ways to solve transportation issues such as poorly maintained roads, traffic jams, and the high rate of accidents, researchers need access to the most current datasets on a variety of topics. But tracking down information about roadway conditions, congestion, and other statistics across multiple websites can be time-consuming. Plus, the data isn’t always accurate.

The new National Transportation Data & Analytics Solution (NTDAS), developed with the help of IEEE, makes it easier to retrieve, visualize, and analyze data in one place. NTDAS combines advanced research tools with access to high-quality transportation datasets from the U.S. Federal Highway Administration’s National Highway System and the entire Traffic Message Channel network, which distributes information on more than 1 million road segments. Anonymous data on millions of cars and trucks is generated from vehicle probes, which are vehicles equipped with GPS or global navigation satellite systems that gather traffic data on location, speed, and direction. This information helps transportation planners improve traffic flow, make transportation networks more efficient, and plan budgets.

The platform is updated monthly and contains archival data back to 2017.

“The difference between NTDAS and other competitors is that our data comes from a trusted source that means the most: the U.S. Federal Highway Administration,” says Lavanya Sayam, senior manager of data analytics alliances and programs for IEEE Global Products and Marketing. “The data has been authenticated and validated. The ability to download this massive dataset provides an unparalleled ease to data scientists and machine-learning engineers to explore and innovate.”

IEEE is diversifying its line of products beyond its traditional fields of electrical engineering, Sayam adds. “We are not just focused on electrical or computer science,” she says. “IEEE is so diverse, and this state-of-the-art platform reflects that.”

Robust analytical tools

NTDAS was built in partnership with INRIX, a transportation analytics solutions provider, and the University of Maryland’s Center for Advanced Transportation Technology Laboratory, a leader in transportation science research. INRIX provided the data, while UMD built the analytics tools. The platform leverages the National Performance Management Research Data Set, a highly granular data source from the Federal Highway Administration.

The suite of tools allows users to do tasks such as creating a personal dashboard to monitor traffic conditions on specific roads, downloading raw data for analysis, building animated maps of road conditions, and measuring the flow of traffic. There are tutorials available on the platform on how to use each tool, and templates for creating reports, documents, and pamphlets.

“The difference between National Transportation Data & Analytics Solutions and other competitors is that our data comes from a trusted source that means the most: the U.S. Federal Highway Administration.” —Lavanya Sayam

“This is the first time this type of platform is being offered by IEEE to the global academic institutional audience,” she says. “IEEE is always looking for new ways to serve the engineering community.”

A subscription-based service, NTDAS has multidisciplinary relevance, Sayam says. The use cases it includes serve researchers and educators who need a robust platform that has all the data that helps them conduct analytics in one place, she says. For university instructors, it’s an innovative way to teach the courses, and for students, it’s a unique way to apply what they’ve learned with real-world data and uses.

The platform goes beyond just those working in transportation, Sayam notes. Others who might find NTDAS useful include those who study traffic as it relates to sustainability, the environment, civil engineering, public policy, business, and logistics, she adds.

50 ways to minimize the impact of traffic

NTDAS also includes more than 50 use cases created by IEEE experts to demonstrate how the data could be analyzed. The examples identify ways to protect the environment, better serve disadvantaged communities, support alternative transportation, and improve the safety of citizens. “Data from NTDAS can be easily extrapolated to non-U.S. geographies, making it highly relevant to global researchers,” according to Sayam. This is explained in specific use cases too.

The cases cover topics such as the impact of traffic on bird populations, air-quality issues in underserved communities, and optimal areas to install electric vehicle charging stations.

Two experts covered various strategies for how to use the data to analyze the impact of transportation and infrastructure on the environment in this on-demand webinar held in May.

Thomas Brennan, a professor of civil engineering at the College of New Jersey, discussed how using NTDAS data could aid in better planning of evacuation routes during wildfires, such as determining the location of first responders and traffic congestion in the area, including seasonal traffic. This and other data could lead to evacuating residents faster, new evacuation road signage, and better communication warning systems, he said.

“Traffic systems are super complex and very difficult to understand and model,” said presenter Jane MacFarlane, director of the Smart Cities and Sustainable Mobility Center at the University of California’s Institute of Transportation Studies, in Berkeley. “Now that we have datasets like these, that’s giving us a huge leg up in trying to use them for predictive modeling and also helping us with simulating things so that we can gain a better understanding.”

Watch this short demonstration about the National Transportation Data & Analytics Solutions platform.

“Transportation is a basic fabric of society,” Sayam says. “Understanding its impact is an imperative for better living. True to IEEE’s mission of advancing technology for humanity, NTDAS, with its interdisciplinary relevance, helps us understand the impact of transportation across several dimensions.”

-

Insomniacs Rejoice! This Headband Helps You Fall Asleep

by Tekla S. Perry on 04. June 2024. at 13:06

Elemind, a 5-year-old startup based in Cambridge, Mass., today unveiled a US $349 wearable for neuromodulation, the company’s first product. According to cofounder and CEO Meredith Perry, the technology tracks the oscillation of brain waves using electroencephalography (EEG) sensors that detect the electrical activity of the brain and then influence those oscillations using bursts of sound delivered via bone conduction.

Elemind’s first application for this wearable aims to suppress alpha waves to help induce sleep. There are other wearables on the market that monitor brain waves and, through biofeedback, encourage users to actively modify their alpha patterns. Elemind’s headband appears to be the first device to use sound to directly influence the brain waves of a passive user.

In a clinical trial, says Perry [no relation to author], 76 percent of subjects fell asleep more quickly. Those who did see a difference averaged 48 percent less time to progress from awake to asleep. The results were similar to those of comparable trials of pharmaceutical sleep aids, Perry indicated.

“For me,” Perry said, “it cuts through my rumination, quiets my thinking. It’s like noise cancellation for the brain.”

I briefly tested Elemind’s headband in May. I found it comfortable, with a thick cushioned band that sits across the forehead connected to a stretchy elastic loop to keep it in place. In the band are multiple EEG electrodes, a processor, a three-axis accelerometer, a rechargeable lithium-polymer battery, and custom electronics that gather the brain’s electrical signals, estimate their phase, and generate pink noise through a bone-conduction speaker. The whole thing weighs about 60 grams—about as much as a small kiwi fruit.

My test conditions were far from optimal for sleep: early afternoon, a fairly bright conference room, a beanbag chair as bed, and a vent blowing. And my test lasted just 4 minutes. I can say that I didn’t find the little bursts of pink noise (white noise without the higher frequencies) unpleasant. And since I often wear an eye mask, feeling fabric on my face wasn’t disturbing. It wasn’t the time or place to try for sound sleep, but I—and the others in the room—noted that after 2 minutes I was yawning like crazy.

How Elemind tweaks brain waves

What was going on in my brain? Briefly, different brain states are associated with different frequencies of waves. Someone who is relaxed with eyes closed but not asleep produces alpha waves at around 10 hertz. As they drift off to sleep, the alpha waves are supplanted by theta waves, at around 5 Hz. Eventually, the delta waves of deep sleep show up at around 1 Hz.

Ryan Neely, Elemind’s vice president of science and research, explains: “As soon as you put the headband on,” he says, “the EEG system starts running. It uses straightforward signal processing with bandpass filtering to isolate the activity in the 8- to 12-Hz frequency range—the alpha band.”

“Then,” Neely continues, “our algorithm looks at the filtered signal to identify the phase of each oscillation and determines when to generate bursts of pink noise.”

To help a user fall asleep more quickly [top], bursts of pink noise are timed to generate a brain response that is out of phase with alpha waves and so suppresses them. To enhance deep sleep [bottom], the pink noise is timed to generate a brain response that is in phase with delta waves.Source: Elemind

To help a user fall asleep more quickly [top], bursts of pink noise are timed to generate a brain response that is out of phase with alpha waves and so suppresses them. To enhance deep sleep [bottom], the pink noise is timed to generate a brain response that is in phase with delta waves.Source: ElemindThese auditory stimuli, he explains, create ripples in the waves coming from the brain. Elemind’s system tries to align these ripples with a particular phase in the wave. Because there is a gap between the stimulus and the evoked response, Elemind tested its system on 21 people and calculated the average delay, taking that into account when determining when to trigger a sound.

To induce sleep, Elemind’s headband targets the trough in the alpha wave, the point at which the brain is most excitable, Neely says.

“You can think of the alpha rhythm as a gate for communication between different areas of the brain,” he says. “By interfering with that communication, that coordination between different brain areas, you can disrupt patterns, like the ruminations that keep you awake.”

With these alpha waves suppressed, Neely says, the slower oscillations, like the theta waves of light sleep, take over.

Elemind doesn’t plan to stop there. The company plans to add an algorithm that addresses delta waves, the low-frequency 0.5- to 2-Hz waves characteristic of deep sleep. Here, Elemind’s technology will attempt to amplify this pattern with the intent of improving sleep quality.

Is this safe? Yes, Neely says, because auditory stimulation is self-limiting. “Your brain waves have a natural space they can occupy,” he explains, “and this stimulation just moved it within that natural space, unlike deep-brain stimulation, which can move the brain activity outside natural parameters.”

Going beyond sleep to sedation, memory, and mental health

Applications may eventually go beyond inducing and enhancing sleep. Researchers at the University of Washington and McGill University have completed a clinical study to determine if Elemind’s technology can be used to increase the pain threshold of subjects undergoing sedation. The results are being prepared for peer review.

Elemind is also working with a team involving researchers at McGill and the Leuven Brain Institute to determine if the technology can enhance memory consolidation in deep sleep and perhaps have some usefulness for people with mild cognitive impairment and other memory disorders.

Neely would love to see more applications investigated in the future.

“Inverse alpha stimulation [enhancing instead of suppressing the signal] could increase arousal,” he says. “That’s something I’d love to look into. And looking into mental-health treatment would be interesting, because phase coupling between the different brain regions appears to be an important factor in depression and anxiety disorders.”

Perry, who previously founded the wireless power startup UBeam, cofounded Elemind with four university professors with expertise in neuroscience, optogenetics, biomedical engineering, and artificial intelligence. The company has $12 million in funding to date and currently has 13 employees.

Preorders at $349 start today for beta units, and Elemind expects to start general sales later this year. The company will offer customers an optional membership at $7 to $13 monthly that will allow cloud storage of sleep data and access to new apps as they are released.

-

Hybrid Bonding Plays Starring Role in 3D Chips

by Samuel K. Moore on 04. June 2024. at 12:00

Researchers at the IEEE Electronic Components and Technology Conference (ECTC) last week pushed the state of the art in a technology that is becoming critical to cutting-edge processors and memory. Called hybrid bonding, the technology stacks two or more chips atop each other in the same package, allowing chipmakers to increase the number of transistors in their processors and memories despite a general slowdown in the pace of the traditional transistor shrinking that once defined Moore’s Law. Research groups from major chipmakers and universities demonstrated a variety of hard-fought improvements, with a few—including from Applied Materials, Imec, Intel, and Sony—showing results that could lead to a record density of connections between 3D stacked chips of around 7 million links in a square millimeter of silicon.

All those connections are needed because of the new nature of progress in semiconductors, Intel’s Yi Shi told engineers at ECTC. As Intel general manager of technology development Ann Kelleher explained to IEEE Spectrum in 2022, Moore’s Law is now governed by a concept called system technology co-optimization, or STCO. In STCO, a chip’s functions, such as cache memory, input/output, and logic are separated out and made using the best manufacturing technology for each. Hybrid bonding and other advanced packaging tech can then reassemble them so that they work like a single piece of silicon. But that can only happen with a high density of connections that can shuttle bits between pieces of silicon with little delay or energy consumption.

Hybrid bonding is not the only advanced packaging technology in use, but it provides the highest density of vertical connections. And it dominated ECTC, making up about one-fifth of the research presented, according to Chris Scanlan, senior vice president of technology at Besi, whose tools were behind several of the breakthroughs.

“It’s difficult to say what will be the limit. Things are moving very fast.” —Jean-Charles Souriau, CEA Leti

In hybrid bonding, copper pads are constructed at the top face of each chip. The copper is surrounded by insulation, usually silicon oxide, and the pads themselves are slightly recessed from the surface of the insulation. After the oxide is chemically modified, the two chips are then pressed together face-to-face, so the recessed pads align with each. This sandwich is then slowly heated, causing the copper to expand across the gap, connecting the two chips.

Hybrid bonding can either attach individual chips of one size to a wafer full of chips of a larger size or used to bond two full wafers of chips of the same size together. Thanks in part to its use in camera chips, the latter is a more mature process than the former. Imec, for example, reported some of the most dense wafer-on-wafer (WoW) bonds ever with a bond-to-bond distance (or pitch) of just 400 nanometers. The same research center managed a 2-micrometer pitch for the chip-on-wafer (CoW) scenario. (Commercial chips today have connections about 9 μm apart.)

Hybrid bonding starts by forming recessed copper pads at the top of the chip [top]. The surrounding oxide dielectric bonds when the two chips are pressed together [middle]. Annealing expands the copper to form a conductive connection [bottom].

Hybrid bonding starts by forming recessed copper pads at the top of the chip [top]. The surrounding oxide dielectric bonds when the two chips are pressed together [middle]. Annealing expands the copper to form a conductive connection [bottom].

“With the equipment available, it’s easier to align wafer to wafer than chip to wafer. Most processes for microelectronics are made for [full] wafers,” says Jean-Charles Souriau, scientific leader in integration and packaging at the French research organization, CEA Leti. However, it’s chip-on-wafer (or die-to-wafer) that’s making a splash in high-end processors such as AMD’s Epyc line, where the technique is used to assemble compute cores and cache memory in its advanced CPUs and AI accelerators.

In pushing for tighter and tighter pitches for both scenarios, researchers focused on making surfaces fractionally flatter, getting bound wafers to stick together better, and cutting the time and complexity of the whole process. Getting it right could ultimately mean enabling a revolution in how chips are designed.

WoW, those are some tight pitches

The wafer-on-wafer (WoW) research that reported the tightest pitches—500 nm to 360 nm—all spent a lot of effort on one thing: flatness. To bind two wafers together with 100-nm-level accuracy, the whole wafer has to be nearly perfectly flat. If it’s bowed or warped, whole sections of the materials won’t connect.

Flattening wafers is the job of a process called chemical mechanical planarization, or CMP. It’s key to chipmaking generally, especially for the parts of the process that produce the layers of interconnects above the transistors.

“CMP is a key parameter we have to control for hybrid bonding,” says Souriau. Results presented this week at ECTC took CMP to another level, not just flattening across the wafer but reducing mere nanometers of roundness on the insulation between the copper pads to ensure better connections.

Other research focused on ensuring those flattened parts stuck together strongly enough by experimenting with different surface materials such as silicon carbonitride instead of silicon oxide or by using different schemes to chemically activate the surface. Initially, when wafers or dies are pressed together, they are held in place with relatively weak hydrogen bonds, and the concern is ensuring that everything stays in place between the bonding and further steps. Bound wafers and chips are then heated slowly (a process called annealing) to form stronger chemical bonds. Just how strong these bonds are—and how to even figure that out—was the subject of a lot of research at ECTC.

Part of that final bond strength would come from the copper connections as well. The annealing step expands the copper across the gap to form a conductive bridge. Controlling the size of that gap is key, explained Samsung’s Seung Ho Hahn. Too much of a gap and the copper won’t connect. Too little and it will push the wafers apart. It’s a matter of nanometers, and Hahn reported research on a new chemical process that hopes to get it just right by etching away the copper a single atomic layer at a time.

The quality of the connection counts, too. Even after the copper expands, most schemes showed that the metal’s grain boundaries don’t cross from one side to another. Such a crossing reduces a connection’s electrical resistance and should boost its reliability. Researchers at Tohoku University in Japan reported a new metallurgical scheme that could finally generate large, single grains of copper that cross the boundary. “This is a drastic change,” said Takafumi Fukushima, an associate professor at Tohoku University. “We are now analyzing what underlies it.”

“I think it’s possible to make more than 20-layer stack using this technology.” —Hyeonmin Lee, Samsung

Other experiments focused on streamlining the hybrid bonding process. Several sought to reduce the annealing temperature needed to form bonds—typically around 300 °C—motivated by the potential to reduce any risk of damage to the chips from the prolonged heating. And researchers from Applied Materials presented progress on a method to radically reduce the time needed for annealing—from hours to just 5 minutes.

CoWs that are outstanding in the field

Chip-on-wafer (CoW) hybrid bonding is more useful to industry at the moment: It allows chipmakers to stack chiplets of different sizes together, and to test each chip before it’s bound to another, ensuring that they aren’t fatally dooming an expensive CPU with a single flawed part.

But CoW comes with all of the difficulties of WoW and fewer of the options to alleviate them. For example, CMP is designed to flatten wafers, not individual dies. Once dies have been cut from their source wafer and tested, there’s less that can be done to improve their readiness for bonding.

Nevertheless, Intel reported CoW hybrid bonds with a 3-μm pitch, and Imec managed 2 μm, largely by making the transferred dies very flat while they were still attached to the wafer and keeping them extra clean going forward. Efforts by both groups used plasma etching to dice up the dies instead of the usual method, which uses a specialized blade. Plasma won’t lead to chipping at the edges, which creates debris that interferes with connections. It also allowed the Imec group to shape the die, making chamfered corners that relieved mechanical stress that could break connections.

CoW hybrid bonding is going to be critical to the future of high-bandwidth memory (HBM), several researchers told IEEE Spectrum. HBM is a stack of DRAM dies atop a control logic chip—currently 8 to 12 dies high. Often placed within the same package as high-end GPUs, HBM is crucial to providing the tsunami of data needed to run large language models like ChatGPT. Today, HBM dies are stacked using so-called microbump technology, in which tiny balls of solder between each layer are surrounded by an organic filler.

But with AI pushing memory demand even higher, DRAM makers want to do 20 layers or more in HBM chips. However, the volume microbumps take up mean that these stacks will soon be too tall to fit in the package with GPUs. Hybrid bonding would not just shrink the height of HBMs, it should also make it easier to remove excess heat from the package, because there is less thermal resistance between its layers.

A 200-nanometer WoW pitch is not just possible, but desirable.

At ECTC, Samsung engineers showed that a hybrid bonding scheme could make a 16-layer HBM stack. “I think it’s possible to make more than 20-layer stack using this technology,” said Hyeonmin Lee, a senior engineer at Samsung.

Other new CoW technology could help bring hybrid bonding to high-bandwidth memory. Though they didn’t present research on this at ECTC, researchers at CEA Leti are working on so-called self-alignment technology, says Souriau. That would help ensure CoW connections using chemical processes. Some parts of each surface would be made hydrophobic and some hydrophilic, resulting in surfaces that would slide into place automatically.

At ECTC, researchers at Tohoku University and Yamaha Robotics reported work on a similar scheme, using the surface tension of water to align 5-μm pads on experimental DRAM chips with better than 50-nm accuracy.

How far can hybrid bonding go?

Researchers will almost certainly keep pushing the pitch of hybrid bonding connections. A 200-nm WoW pitch is not just possible but desirable, Han-Jong Chia, a program manager pathfinding systems at Taiwan Semiconductor Manufacturing Co., told engineers at ECTC. Within two years, TSMC plans to introduce a technology called backside power delivery. (Intel plans it for the end of this year.) That’s a technology that puts the chip’s chunky power-delivery interconnects beneath the silicon instead of above it. With those out of the way, the uppermost interconnect levels can connect better to smaller hybrid bonding bond pads, TSMC researchers calculate. Back side power delivery with 200-nm bond pads would cut down the capacitance of 3D connections so much that the product of energy efficiency and signal delay would be as much as nine times as high as what can be achieved with 400-nm bond pads.

At some point in the future, if bond pitches are narrowed even further, Chia suggested, it might become practical to “fold” blocks of circuitry so they are built across two wafers. That way some of the longer connections within the block might be made shorter by the vertical pathway, potentially speeding computations and lowering power consumption.

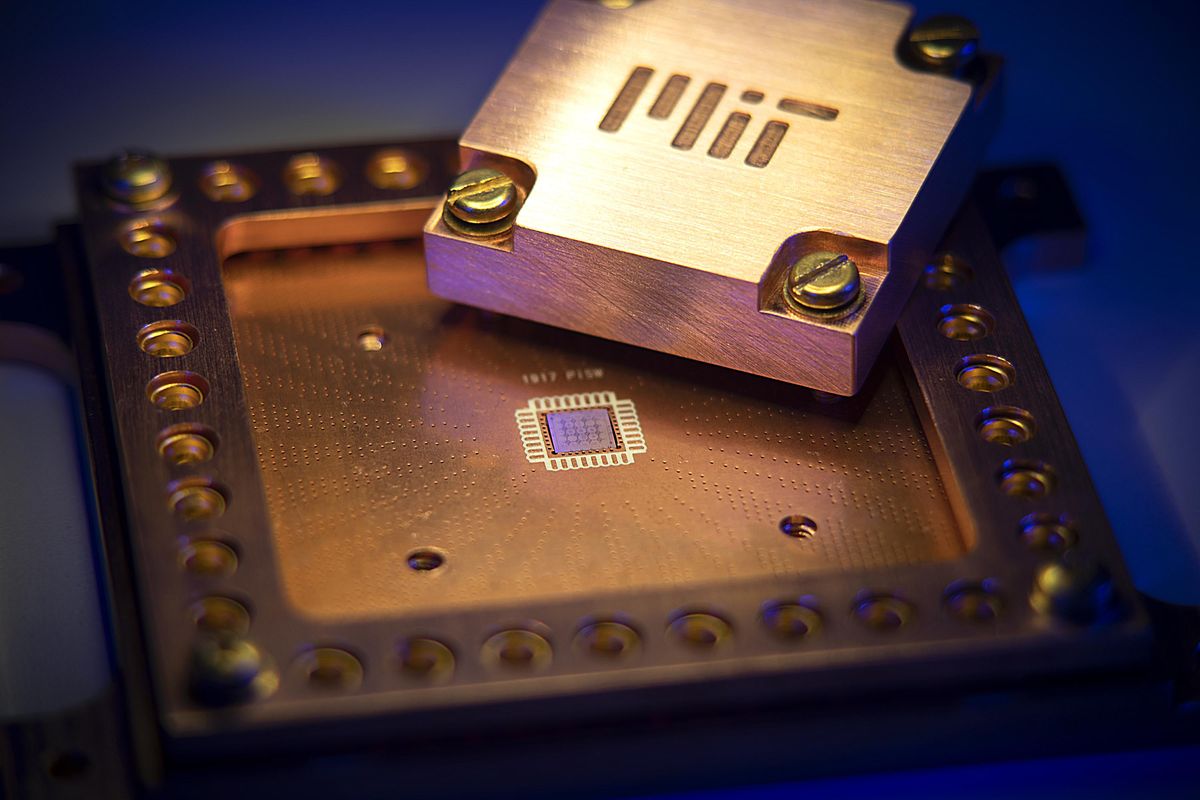

And hybrid bonding may not be limited to silicon. “Today there is a lot of development in silicon-to-silicon wafers, but we are also looking to do hybrid bonding between gallium nitride and silicon wafers and glass wafers…everything on everything,” says CEA Leti’s Souriau. His organization even presented research on hybrid bonding for quantum-computing chips, which involves aligning and binding superconducting niobium instead of copper.

“It’s difficult to say what will be the limit,” Souriau says. “Things are moving very fast.”

-

Quantum Navigational Tech Takes Flight in New Trial

by Margo Anderson on 03. June 2024. at 18:22

A short-haul aircraft in the United Kingdom recently became the first airborne platform to test delicate quantum technologies that could usher in a post-GPS world—in which satellite-based navigation (be it GPS, BeiDou, Galileo, or others) cedes its singular place as a trusted navigational tool. The question now is how soon will it take for this quantum tomorrow to actually arrive.

But is this tech just around the corner, as its proponents suggest? Or will the world need to wait until the 2030s or beyond, as skeptics maintain. Whenever the technology can scale up, potential civilian applications will be substantial.

“The very first application or very valuable application is going to be autonomous shipping,” says Max Perez, vice president for strategic initiatives at the Boulder, Colo.–based company Infleqtion. “As we get these systems down smaller, they’re going to start to be able to address other areas like autonomous mining, for example, and other industrial settings where GPS might be degraded. And then, ultimately, the largest application will be generalized, personal autonomous vehicles—whether terrestrial or air-based.”

The big idea Infleqtion and its U.K. partners are testing is whether the extreme sensitivity that quantum sensors can provide is worth the trade-off of all the expensive kit needed to miniaturize such tech so it can fit on a plane, boat, spacecraft, car, truck, or train.

Turning Bose-Einstein Condensates Into Navigational Tools

At the core of Infleqtion’s technology is a state of matter called a Bose-Einstein condensate (BEC), which can be made to be extremely sensitive to acceleration. And in the absence of an external GPS signal, an aircraft that can keep a close tally on its every rotation and acceleration is an aircraft that can infer its exact location relative to its last known position.

As Perez describes it—the company has not yet published a paper on its latest, landmark accomplishment—Infleqtion’s somewhat-portable BEC device occupies 8 to 10 rack units of space. (One rack unit represents a standard server rack’s width of 48.3 centimeters and a standard server rack depth of 60–100 cm.)

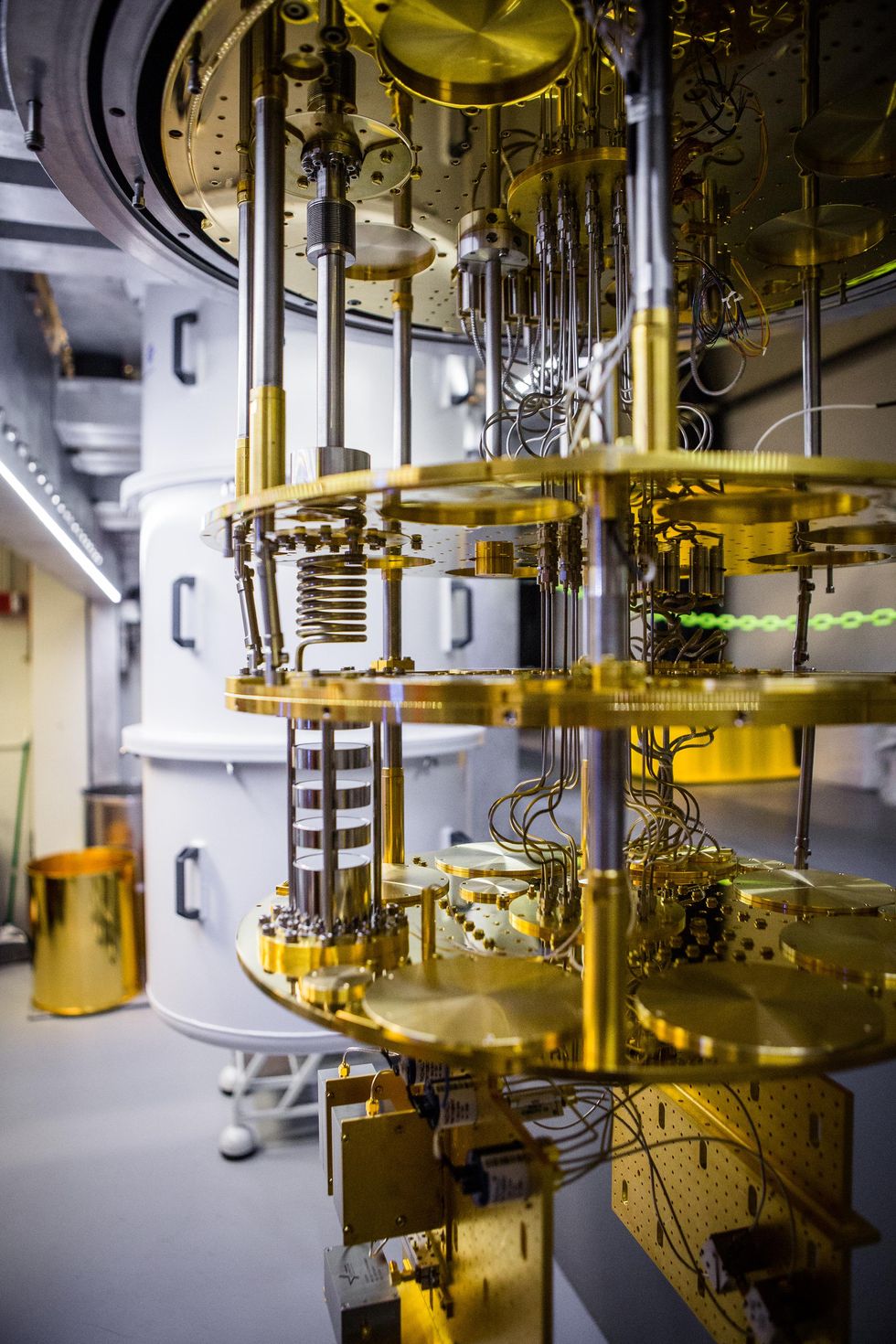

Scientists tested delicate Bose-Einstein condensates in their instruments, which could one day undergird ultrasensitive accelerometers.Qinetiq

Scientists tested delicate Bose-Einstein condensates in their instruments, which could one day undergird ultrasensitive accelerometers.QinetiqIn May, the company flew its rig aboard a British Aerospace 146 (BAe 146/Avro RJ100) tech demonstrator aircraft. Inside the rig, a set of lasers blasted a small, supercooled cloud of rubidium atoms to establish a single quantum state among the atoms. The upshot of this cold atom trap is to create ultrasensitive quantum conditions among the whole aggregation of atoms, which is then a big enough cloud of matter to be able to be manipulated with standard laboratory equipment.

Using the quantum wave-particle duality, in which matter behaves both like tiny billiard balls and wave packets, engineers can then use lasers and magnetic fields to split the BEC cloud into two or more coherent matter-wave packets. When later recombined, the interference patterns of the multiple wave packets are studied to discover even the most minuscule accelerations—tinier than conventional accelerometers could measure—to the wave packets’ positions in three-dimensional space.

That’s the theoretical idea, at least.

Real-World Conditions Muddy Timetables

In practice, any BEC-based accelerometer would need to at least match the sensitivity of existing, conventional accelerometer technologies.

“The best inertial systems in the world, based on ring laser gyroscopes, or fiber-optic gyroscopes, can...maintain a nautical mile of precision over about two weeks of mission,” Perez says. “That’s the standard.”

The Infleqtion rig has provided only a proof of principle for creating a manipulable BEC state in a rubidium cloud, Perez adds, so there’s no one-to-one comparison yet available for the quantum accelerometer technology. That said, he expects Infleqtion to be able to either maintain the same nautical-mile precision over a month or more mission time—or, conversely, increase the sensitivity over a week’s mission to something like one-tenth of a nautical mile.

The eventual application space for the technology is vast, says Doug Finke, chief content officer at the New York City–based market research firm Global Quantum Intelligence.

“Quantum navigation devices could become the killer application for quantum-sensing technology,” Finke says. “However, many challenges remain to reduce the cost, size, and reliability. But potentially, if this technology follows it similar path to what happened in computing, from room-size mainframes to something that fits inside one’s pocket, it could become ubiquitous and possibly even replace GPS later this century.”

The timeframe for such a takeover remains an unanswered question. “It won’t happen immediately due to the engineering challenges still to be resolved,” Finke says. “And the technology may require many more years to reach maturation.”

Dana Goward, president of the Alexandria, Va.–based Resilient Navigation and Timing Foundation, even ventures a prediction. “It will be 10 to 15 years at least before we see something that is practical for broad application,” he says.

Perez says that by 2026, Infleqtion will be testing the reliability of its actual accelerometer technology—not just setting up a BEC in midflight, as it did in May. “It’s basically trading off getting the technology out there a little faster versus something that is more precise for more demanding applications that’ll be just behind that,” Perez says.

UPDATE 4 June 2024: The story was updated to modify the accuracy estimate for the best inertial navigation systems today—from one nautical mile per one-week mission (as a previous version of this story stated) to one nautical mile per two-week mission.

-

How Online Privacy Is Like Fishing

by Bruce Schneier on 03. June 2024. at 11:00

Microsoft recently caught state-backed hackers using its generative AI tools to help with their attacks. In the security community, the immediate questions weren’t about how hackers were using the tools (that was utterly predictable), but about how Microsoft figured it out. The natural conclusion was that Microsoft was spying on its AI users, looking for harmful hackers at work.

Some pushed back at characterizing Microsoft’s actions as “spying.” Of course cloud service providers monitor what users are doing. And because we expect Microsoft to be doing something like this, it’s not fair to call it spying.

We see this argument as an example of our shifting collective expectations of privacy. To understand what’s happening, we can learn from an unlikely source: fish.

In the mid-20th century, scientists began noticing that the number of fish in the ocean—so vast as to underlie the phrase “There are plenty of fish in the sea”—had started declining rapidly due to overfishing. They had already seen a similar decline in whale populations, when the post-WWII whaling industry nearly drove many species extinct. In whaling and later in commercial fishing, new technology made it easier to find and catch marine creatures in ever greater numbers. Ecologists, specifically those working in fisheries management, began studying how and when certain fish populations had gone into serious decline.

One scientist, Daniel Pauly, realized that researchers studying fish populations were making a major error when trying to determine acceptable catch size. It wasn’t that scientists didn’t recognize the declining fish populations. It was just that they didn’t realize how significant the decline was. Pauly noted that each generation of scientists had a different baseline to which they compared the current statistics, and that each generation’s baseline was lower than that of the previous one.

What seems normal to us in the security community is whatever was commonplace at the beginning of our careers.

Pauly called this “shifting baseline syndrome” in a 1995 paper. The baseline most scientists used was the one that was normal when they began their research careers. By that measure, each subsequent decline wasn’t significant, but the cumulative decline was devastating. Each generation of researchers came of age in a new ecological and technological environment, inadvertently masking an exponential decline.

Pauly’s insights came too late to help those managing some fisheries. The ocean suffered catastrophes such as the complete collapse of the Northwest Atlantic cod population in the 1990s.

Internet surveillance, and the resultant loss of privacy, is following the same trajectory. Just as certain fish populations in the world’s oceans have fallen 80 percent, from previously having fallen 80 percent, from previously having fallen 80 percent (ad infinitum), our expectations of privacy have similarly fallen precipitously. The pervasive nature of modern technology makes surveillance easier than ever before, while each successive generation of the public is accustomed to the privacy status quo of their youth. What seems normal to us in the security community is whatever was commonplace at the beginning of our careers.

Historically, people controlled their computers, and software was standalone. The always-connected cloud-deployment model of software and services flipped the script. Most apps and services are designed to be always-online, feeding usage information back to the company. A consequence of this modern deployment model is that everyone—cynical tech folks and even ordinary users—expects that what you do with modern tech isn’t private. But that’s because the baseline has shifted.

AI chatbots are the latest incarnation of this phenomenon: They produce output in response to your input, but behind the scenes there’s a complex cloud-based system keeping track of that input—both to improve the service and to sell you ads.

Shifting baselines are at the heart of our collective loss of privacy. The U.S. Supreme Court has long held that our right to privacy depends on whether we have a reasonable expectation of privacy. But expectation is a slippery thing: It’s subject to shifting baselines.

The question remains: What now? Fisheries scientists, armed with knowledge of shifting-baseline syndrome, now look at the big picture. They no longer consider relative measures, such as comparing this decade with the last decade. Instead, they take a holistic, ecosystem-wide perspective to see what a healthy marine ecosystem and thus sustainable catch should look like. They then turn these scientifically derived sustainable-catch figures into limits to be codified by regulators.

In privacy and security, we need to do the same. Instead of comparing to a shifting baseline, we need to step back and look at what a healthy technological ecosystem would look like: one that respects people’s privacy rights while also allowing companies to recoup costs for services they provide. Ultimately, as with fisheries, we need to take a big-picture perspective and be aware of shifting baselines. A scientifically informed and democratic regulatory process is required to preserve a heritage—whether it be the ocean or the Internet—for the next generation.

-

Lord Kelvin and His Analog Computer

by Allison Marsh on 02. June 2024. at 13:00

In 1870, William Thomson, mourning the death of his wife and flush with cash from various patents related to the laying of the first transatlantic telegraph cable, decided to buy a yacht. His schooner, the Lalla Rookh, became Thomson’s summer home and his base for hosting scientific parties. It also gave him firsthand experience with the challenge of accurately predicting tides.

Mariners have always been mindful of the tides lest they find themselves beached on low-lying shoals. Naval admirals guarded tide charts as top-secret information. Civilizations recognized a relationship between the tides and the moon early on, but it wasn’t until 1687 that Isaac Newton explained how the gravitational forces of the sun and the moon caused them. Nine decades later, the French astronomer and mathematician Pierre-Simon Laplace suggested that the tides could be represented as harmonic oscillations. And a century after that, Thomson used that concept to design the first machine for predicting them.

Lord Kelvin’s Rising Tide

William Thomson was born on 26 June 1824, which means this month marks his 200th birthday and a perfect time to reflect on his all-around genius. Thomson was a mathematician, physicist, engineer, and professor of natural philosophy. Queen Victoria knighted him in 1866 for his work on the transatlantic cable, then elevated him to the rank of baron in 1892 for his contributions to thermodynamics, and so he is often remembered as Lord Kelvin. He determined the correct value of absolute zero, for which he is honored by the SI unit of temperature—the kelvin. He dabbled in atmospheric electricity, was a proponent of the vortex theory of the atom, and in the absence of any knowledge of radioactivity made a rather poor estimation of the age of the Earth, which he gave as somewhere between 24 million and 400 million years.

William Thomson, also known as Lord Kelvin, is best known for establishing the value of absolute zero. He believed in the practical application of scientific knowledge and invented a wide array of useful, and beautiful, devices. Pictorial Press/Alamy

William Thomson, also known as Lord Kelvin, is best known for establishing the value of absolute zero. He believed in the practical application of scientific knowledge and invented a wide array of useful, and beautiful, devices. Pictorial Press/AlamyThomson’s tide-predicting machine calculated the tide pattern for a given location based on 10 cyclic constituents associated with the periodic motions of the Earth, sun, and moon. (There are actually hundreds of periodic motions associated with these objects, but modern tidal analysis uses only the 37 of them that have the most significant effects.) The most notable one is the lunar semidiurnal, observable in areas that have two high tides and two low tides each day, due to the effects of the moon. The period of a lunar semidiurnal is 12 hours and 25 minutes—half of a lunar day, which lasts 24 hours and 50 minutes.

As Laplace had suggested in 1775, each tidal constituent can be represented as a repeating cosine curve, but those curves are specific to a location and can be calculated only through the collection of tidal data. Luckily for Thomson, many ports had been logging tides for decades. For places that did not have complete logs, Thomson designed both an improved tide gauge and a tidal harmonic analyzer.

On Thomson’s tide-predicting machine, each of 10 components was associated with a specific tidal constituent and had its own gearing to set the amplitude. The components were geared together so that their periods were proportional to the periods of the tidal constituents. A single crank turned all of the gears simultaneously, having the effect of summing each of the cosine curves. As the user turned the crank, an ink pen traced the resulting complex curve on a moving roll of paper. The device marked each hour with a small horizontal mark, making a deeper notch each day at noon. Turning the wheel rapidly allowed the user to run a year’s worth of tide readings in about 4 hours.

Although Thomson is credited with designing the machine, in his paper “The Tide Gauge, Tidal Harmonic Analyser, and Tide Predicter” (published in Minutes of the Proceedings of the Institution of Civil Engineers), he acknowledges a number of people who helped him solve specific problems. Craftsman Alexander Légé drew up the plan for the screw gearing for the motions of the shafts and constructed the initial prototype machine and subsequent models. Edward Roberts of the Nautical Almanac Office completed the arithmetic to express the ratio of shaft speeds. Thomson’s older brother, James, a professor of civil engineering at Queen’s College Belfast, designed the disk-globe-and-cylinder integrator that was used for the tidal harmonic analyzer. Thomson’s generous acknowledgments are a reminder that the work of engineers is almost always a team effort.

Like Thomson’s tide-prediction machine, these two devices, developed at the U.S. Coast and Geodetic Survey, also looked at tidal harmonic oscillations. William Ferrel’s machine [left] used 19 tidal constituents, while the later machine by Rollin A. Harris and E.G. Fischer [right], relied on 37 constituents. U.S. Coast and Geodetic Survey/NOAA

Like Thomson’s tide-prediction machine, these two devices, developed at the U.S. Coast and Geodetic Survey, also looked at tidal harmonic oscillations. William Ferrel’s machine [left] used 19 tidal constituents, while the later machine by Rollin A. Harris and E.G. Fischer [right], relied on 37 constituents. U.S. Coast and Geodetic Survey/NOAAAs with many inventions, the tide predictor was simultaneously and independently developed elsewhere and continued to be improved by others, as did the science of tide prediction. In 1874 in the United States, William Ferrel, a mathematician with the Coast and Geodetic Survey, developed a similar harmonic analysis and prediction device that used 19 harmonic constituents. George Darwin, second son of the famous naturalist, modified and improved the harmonic analysis and published several articles on tides throughout the 1880s. Oceanographer Rollin A. Harris wrote several editions of the Manual of Tides for the Coast and Geodetic Survey from 1897 to 1907, and in 1910 he developed, with E.G. Fischer, a tide-predicting machine that used 37 constituents. In the 1920s, Arthur Doodson of the Tidal Institute of the University of Liverpool, in England, and Paul Schureman of the Coast and Geodetic Survey further refined techniques for harmonic analysis and prediction that served for decades. Because of the complexity of the math involved, many of these old brass machines remained in use into the 1950s, when electronic computers finally took over the work of predicting tides.

What Else Did Lord Kelvin Invent?

As regular readers of this column know, I always feature a museum object from the history of computer or electrical engineering and then spin out a story. When I started scouring museum collections for a suitable artifact for Thomson, I was almost paralyzed by the plethora of choices.

I considered Thomson’s double-curb transmitter, which was designed for use with the 1858 transatlantic cable to speed up telegraph signals. Thomson had sailed on the HMS Agamemnon in 1857 on its failed mission to lay a transatlantic cable and was instrumental to the team that finally succeeded.

Thomson invented the double-curb transmitter to speed up signals in transatlantic cables.Science Museum Group